XWDJ-350 turbine pulverizer

Applications: Suitable for low hardness material comminution, chemical, pharmaceutical, pesticide, dye, paint, metallurgy, ceramics, food, feed, non metallic minerals and scientific research units, as a fine powder and ultra-fine powder processing is the most ideal, the most effective, the most economical equipment.

Details

XWDJ turbine mill is mainly applied in the low hardness material comminution, chemical, pharmaceutical, pesticide, dye, paint, metallurgy, ceramics, food, feed, non metallic minerals and scientific research units, as a fine powder and ultra-fine powder processing is the most ideal, the most effective, the most economical equipment. The machine is at one end of the housing with rolling bearing spindle, by the motor through a belt drive, drive shaft and fixed on the spindle of the turbine to rotate at high speed. The grinding block, the turbine and the screen ring reasonable components, compact structure, so that the material closely friction in rotating flow and strong impact grinding, and the grinding block between the blade and slot, grind again, through a sieve of regulation can crushing material between 40 -325 mesh. The device has compact and reasonable structure, small volume, low energy consumption, high efficiency, stable rotation, low noise, reliable sealing, no dust pollution, self cooling function, simple installation, easy disassembly and easy maintenance, convenient replacement of damaged parts. According to the characteristics of turbine mill noise, has developed a silencer device, greatly reduce the work noise.Technical parameters:

|

Type |

Rotor diameter(mm) |

Main motor power(kw) |

The engine speed(r/min) |

The fineness of grind(Mesh) |

Yield(kg/h) |

Weight(kg) |

| XWDJ-130 | 130 | 2.2 | 7500 | 10~325 | 3~50 | 30 |

| XWDJ-150 | 150 | 2.2-3 | 7300 | 10~325 | 5~70 | 40 |

| XWDJ-220 | 220 | 4~5.5 | 6000 | 10~325 | 15~150 | 70 |

| XWDJ-250 | 250 | 5.5~7.5 | 6000 | 10~325 | 20~200 | 85 |

| XWDJ-350 | 350 | 11~15 | 4500 | 10~325 | 25~500 | 250 |

| XWDJ-500 | 500 | 18.5~22 | 3250 | 10~325 | 30~1200 | 430 |

| XWDJ-550 | 550 | 22~30 | 2930 | 10~325 | 50~1500 | 480 |

| XWDJ-750 | 750 | 30~37 | 2250 | 10~325 | 60~2000 | 850 |

| Type | A | B | C | Host (L * W * H) |

| XWDJ-130 | 204 | 125 | 170 | 320×150×255 |

| XWDJ-150 | 230 | 140 | 270 | 350×165×280 |

| XWDJ-220 | 235 | 170 | 260 | 505×220×405 |

| XWDJ-250 | 258 | 182 | 378 | 615×212×480 |

| XWDJ-350 | 348 | 250 | 500 | 830×290×660 |

| XWDJ-500 | 435 | 300 | 600 | 1060×350×835 |

| XWDJ-550 | 456 | 300 | 600 | 1080×400×903 |

| XWDJ-750 | 523 | 330 | 900 | 1400×40 0×1130 |

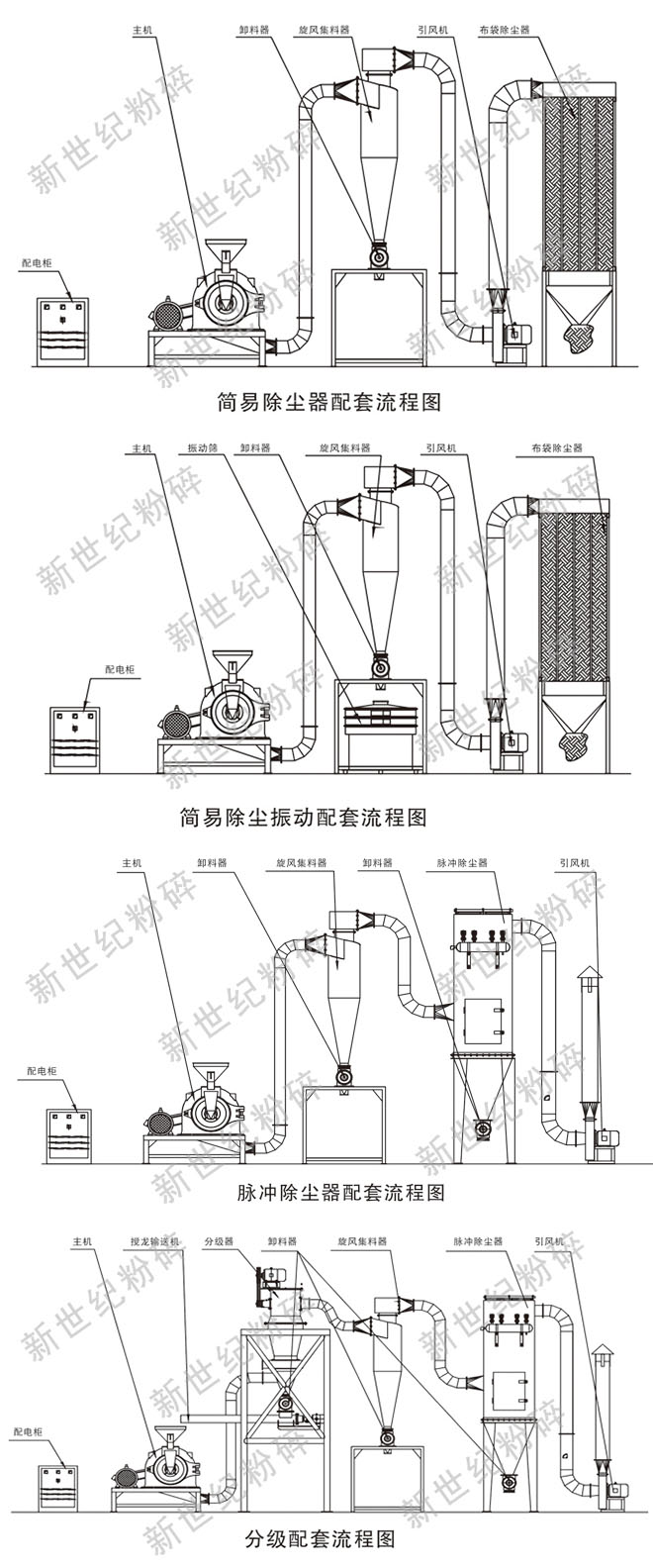

XWDJ turbine mill installation and use matters needing attention

1, the machine installation reference XWDJ turbine pulverizer series with complete sets of equipment simple dust collector design, installation, plus the best of good fixing device on the host machine, fan foot position. (no reinforcement can also use), the flange ring connection position shall be added to the rubber seal gasket or asbestos rope to be sealed, fastening the screw member, make the whole equipment are closely connected, no inclination.

2, the electric control cabinet shall be installed to the normal observation and the operation is convenient in operation personnel, should be grounded.

3, the machine must be carried out after installation of inching test run, pay attention to the rotation direction should be consistent with the sign of rotation machine.

4, the machine before starting with the hand rotating spindle, check whether there is death or abnormal noise, and timely treatment is eliminated, can start the machine, and idle for a few minutes, for everything is normal, then charging.

5, machine to enter into the hopper, in order to ensure the even feeding, to avoid blockage, the device can be installed adjusting feeding speed. Such as the use of anti pressure automatic suction device, the operator should strictly control the feeding speed, not super normal load motor work, must prevent the suction pipe jammed, such as blocking timely dredging, cleaning, and then the normal work.

6, general requirements for processing the material grain size is less than 12mm, the water content of less than 12%.

7, in order to prevent the iron into the machine the damaged parts, should be strictly test material, preferably iron absorption device is arranged in the inlet of.

8, each crushing end, should open the door, check all the strong coupling is loose or not normal wear and tear, and timely processing of intact, while cleaning surface and adhesive on the screen of the material.

9, crushed material is removed from the enclosure cavity, can collect or connected aggregate by the bag directly (aggregate grading) collection device.

10, the machine by replacing the screen, with the aperture of the screen thickness to determine the thickness of the material is crushed, the host back screw fixed the sieve element 4 10mm, rotating 4 screws, open the door, out of the screen, as it is to replace the screen sieve piece, and then is fixed sieve a closed door, began to work.

11, the machine under the condition of normal use, should be timely to the rolling bearing lubricating oil, to avoid bites, damage.

12, such as the wearing parts wear does not work, to be timely as it is replaced.

13, the machine in the user follow the normal rules of use condition, in the factory within twelve months as a result of bad quality of product failure, can't use is responsible for three bags. Does not include spare parts.

14, according to user needs, can provide complete sets of material grading collecting device, and give priority to providing convenience and service.