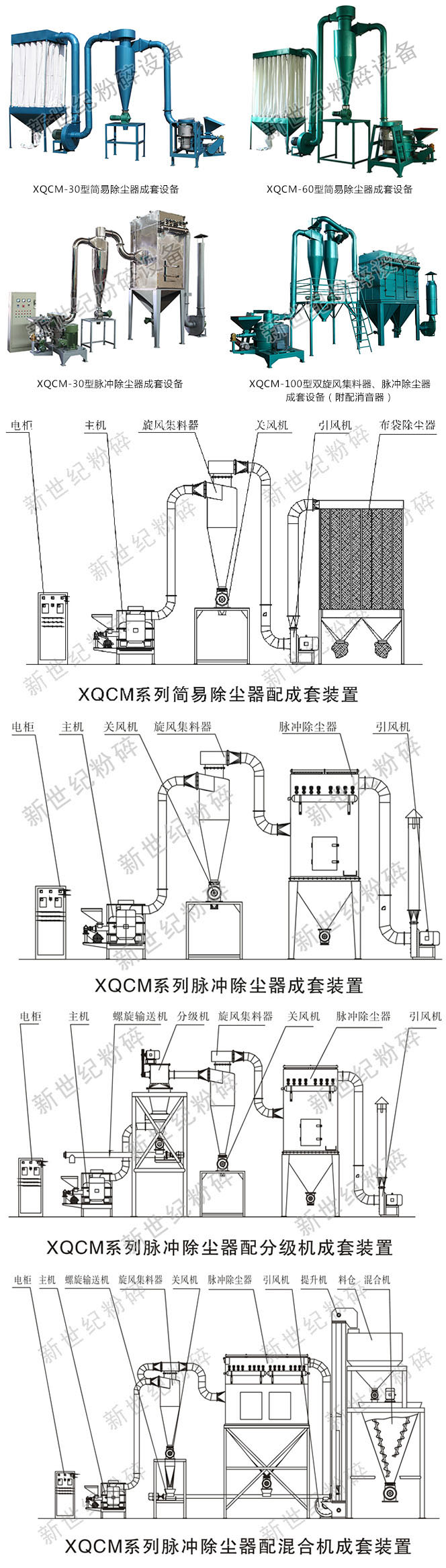

XQCM-130 vortex flow powder machine

Applications: This equipment is used to grind the chemical, food, feed, pharmaceuticals and intermediates, pesticide, pigment, tobacco, paints, dyes and pigments, ceramic, glaze, Takeki, carbon black, white carbon black, graphite, crystals, colloids, non-metallic mineral and biological engineering industry in.

The XQCM series vortex flow powder machine is our company with reference to foreign advanced micro grinding technology, through digestion and absorption is developed. Compared with the machine grinder with our current use, leading performance, suitable for processing a variety of materials, the thermoplastic and fibrous materials are all qualified, product uniform texture, can be crushed into powder and ultra micro powder is the degree of fineness, good performance, energy-saving ideal powder production equipment of high efficiency.

The following characteristics of the device:

1, it is a kind of vertical reflection type pulverizer, can complete the powder grinding and fine powder separating two processing procedures;

2, with the air flow control valve and the grading impeller stepless speed regulator, without stopping the machine can control the product fineness, new type of bag pulse back blowing dust can collect more than 1um powder, fine powder all recycling, do not pollute the environment;

3, the machine with air cooling, crushing low temperature (in case of a special need, can add the most deep water cooling structure pay), especially suitable for processing thermoplastic and fibrous materials (such as chitin biological engineering materials), and overcome the heat sensitive material sticking and bio engineering products problem due to temperature rise and damage the active component, uniform particle size, narrow distribution.

The crushing fineness has reached 1um--300um. The normal continuous grinding, output reached 500 kg --3000 kg per hour.

| Type | XQCM-5 | XQCM-15 | XQCM-20 | XQCM-30 | XQCM-45 | XQCM-60 | XQCM-100 | XQCM-125 | |

| Auxiliary power(kw) | Grinding wheel | 4 | 7.5 | 11 | 22 | 30 | 45 | 55-75 | 90-110 |

| The grading impeller | 0.75 | 0.75 | 1.1 | 4 | 5.5 | 7.5 | 11 | 15 | |

| Feeder | 0.55 | 0.55 | 0.55 | 0.55 | 0.55 | 0.55 | 1.1 | 1.1 | |

| Speed (r/min) | Grinding wheel | 8300 | 7000 | 5500 | 4000 | 3500 | 3000 | 2000 | 1600 |

| The grading impeller | 900-3200 | 800-3000 | 750-3100 | 700-2800 | 650-2600 | 600-2400 | 500-2000 | 400-1600 | |

| Feeder | 20-100 | ||||||||

| Air volume (m3/h) | 250-500 | 700-1200 | 1300-2800 | 2200-3600 | 3600-6500 | 4000-7500 | 8000-12000 | 1200-1600 | |

| Particle size (um) | 10-300 | ||||||||

| Yield (kg/h | 5-150 | 10-200 | 20-600 | 30-1000 | 40-1200 | 50-1500 | 800-3000 | 1200-500 | |

| Weight (kg) | 180 | 350 | 600 | 1000 | 1200 | 2000 | 2500 | 3200 | |

The performance index of crushing various materials (Reference):

| Raw material | Type | Size of raw material | Product size | Throughput (kg/h) |

| Agricultural chemicals | XQCM-30 | φ5MM | 43um | 450 |

| Rice | XQCM-30 | φ2×5mm | 75um | 420 |

| Starch | XQCM-30 | φ2mm | 28um | 300 |

| Inorganic mineral | XQCM-30 | φ5×5mm | 35um | 300 |

| Iron oxide red | XQCM-30 | φ5mm | 32um | 250 |

| Epoxy resin | XQCM-30 | ≤10mm | 75um | 200 |

| PVC | XQCM-30 | φ2mm | 100um | 130 |

| Sawdust | XQCM-30 | φ1mm | 75um | 180 |

| Diatomite | XQCM-30 | ≤12mm | 10um | 400 |

| Rosin | XQCM-30 | ≤12mm | 75um | 650 |

| Fluorspar | XQCM-60 | ≤15mm | 60um | 1200 |

| Sodium chloride | XQCM-60 | ≤15mm | 35um | 1000 |

| Colored glaze | XQCM-60 | ≤1mm | 27um | 1000 |

| Zhu Mutan | XQCM-60 | ≤15mm | 8um | 350 |

| Colloidal powder | XQCM-60 | ≤1mm | 35um | 150 |

| Calcium carbonate | XQCM-30 | ≤φ50um | 7um | 300 |

| Activated bleaching earth | XQCM-30 | ≤φ80um | 2um | 800 |

| Bentonite | XQCM-30 | ≤φ80um | 30um | 120 |

| Calcined kaolin | XQCM-30 | ≤φ10mm | 25um | 220 |

Li Qing | XQCM-30 | ≤φ1mm | 30um | 150 |

| Graphite | XQCM-30 | ≤φ80um | 30um | 200 |

| Phenolic resin | XQCM-60 | ≤φ1mm | 50um | 600 |

| Fluorite powder | XQCM-60 | ≤φ50um | 8um | 700 |

| Teflon | XQCM-30 | ≤φ50um | 1um | 100 |

| Stearic acid | XQCM-30 | ≤φ2mm | 45um | 200 |

| Aluminum hydroxide | XQCM-30 | ≤φ60um | 10um | 200 |

| Bai Tanhei | XQCM-30 | ≤φ50um | 6um | 200 |

Key tips

XQCM pneumatic micro grinding is the ideal equipment for chemical pesticide wettable powder pulverizing, on chitin fiber material can also the normal grinding, got very good application in a lot of chitin and bio engineering industry, replaces the expensive imported equipment.

Aiming at the development of the pesticide industry, the company has developed a pulverizing and classifying the dual function of wettable powder of professional equipment, without stopping the machine can be adjusted powder fineness, the unique grinding system, turbine classification precision, make the product fine and uniform, the fineness of up to 325 --2000 mesh and automatic cooling function. The superfine grinding for stearic acid industry, oxide, pigment industry, chemical pesticide wettable powder is the most ideal crushing equipment.

The chromate factory grinding chrome oxide green sticky, low melting point of difficulty, XQCM grinding through continuous transformation, has been basically overcome the chromium oxide green sticky, discharging difficult problem for grinding, chrome oxide green, crushing opened a convenient channel.