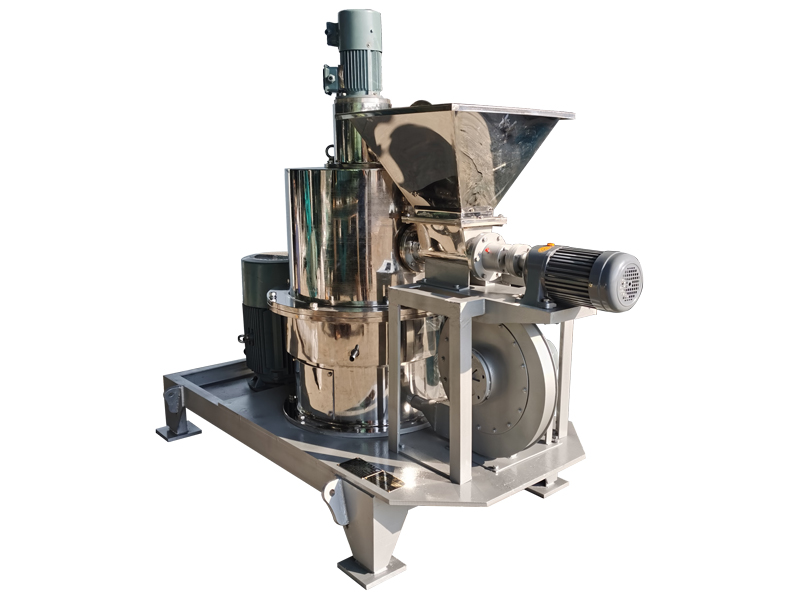

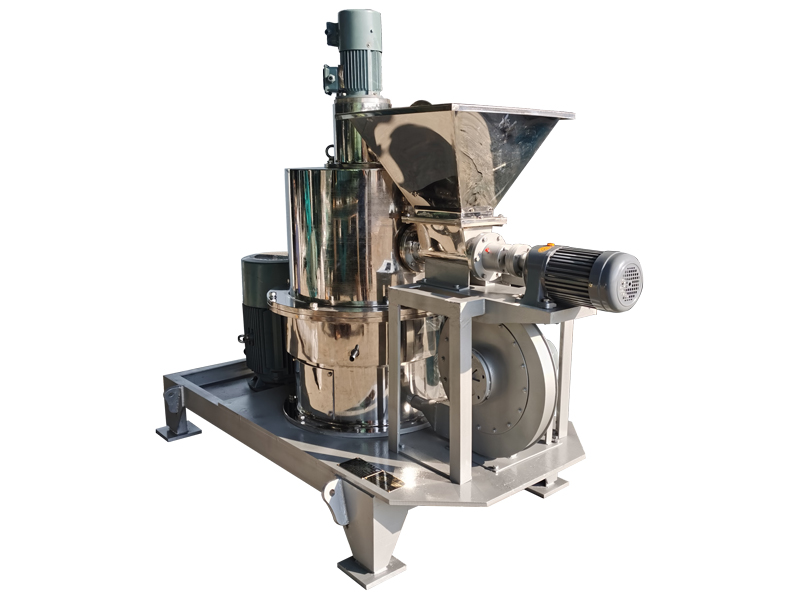

MFJ series wood powder machine

Applications: Main use:This machine is widely used for the grinding and crushing of conventional materials, such as kaolin, limestone, calcite, talc, graphite, and other non flammable and explosive materials with a humidity of less than 8% and a Mohs hardness below level 6. It is particularly suitable for the ult

Main use:

This machine is widely used for the grinding and crushing of conventional materials, such as kaolin, limestone, calcite, talc, graphite, and other non flammable and explosive materials with a humidity of less than 8% and a Mohs hardness below level 6. It is particularly suitable for the ultrafine grinding and processing of wood chips and fiber materials.

Working principle:

The wood powder machine drives the main shaft to rotate through a transmission device. The upper end of the main shaft is connected to a rotor frame, which is equipped with 4-6 laying shafts. The auxiliary shaft is equipped with a grinding wheel and a rocker arm device, forming a swing pivot point. When the main shaft rotates, the auxiliary shaft rotates accordingly, and the grinding wheels on the auxiliary shaft not only revolve around the main shaft, but also rotate around their respective auxiliary shafts. The grinding wheel generates strong centrifugal force during the process of revolution and rotation, and has a strong grinding effect with the stator. The crushed material enters the grinding area composed of the grinding wheel and stator under the driving force of centrifugal force and grinding wheel rotation force field, and is crushed under the strong squeezing force and grinding force. The lower end of the rotor frame is equipped with a scraper system, which is located at the lower end of the grinding wheel device. During the synchronous rotation of the scraper and grinding wheel, the material is scraped and fed into the grinding area composed of the grinding wheel and stator, forming a cushion layer. This material layer is crushed by the internal and external centrifugal force (i.e. extrusion force) generated by the rotation of the grinding wheel, thus achieving the purpose of powder production.

The grading motor drives the grading wheel to rotate, forming a grading effect on the powder.

Due to the continuous grinding of materials in the grinding chamber, the temperature inside the grinding chamber rises rapidly. In order to timely eliminate the heat generated by grinding in the grinding room, a water-cooled jacket is designed outside the grinding room, which can be cooled in time with cooling water.

Features:

1. Compared with other mills under the same power conditions, the output of the grinding wheel increases by 20-30%, and the grinding pressure of the material is increased by 30-40% under the action of high-pressure centrifugal force.

2. Energy saving: When the output and fineness indicators are the same, the energy consumption of crushing wood chips is only about 1/3 of that of the airflow mill.

3. Good product fineness index: When crushing wood chips, the fineness can reach up to 400-600 mesh.

4. This machine has a cooling function and a low temperature during crushing, making it particularly suitable for processing heat sensitive and fiber materials with uniform product particle size.